Get the free tool box meeting format pdf

Show details

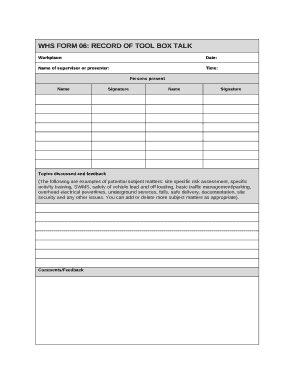

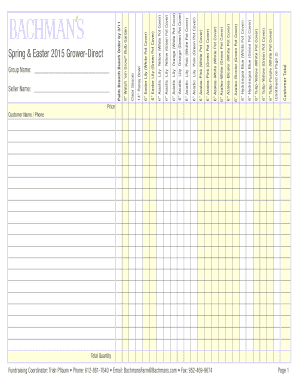

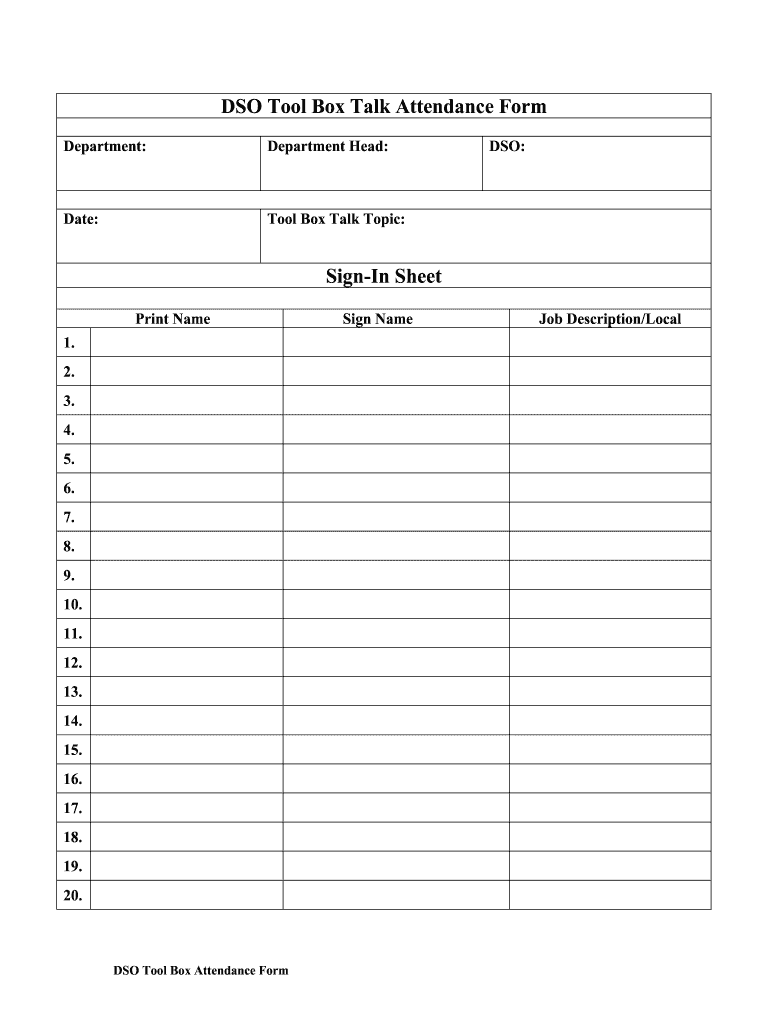

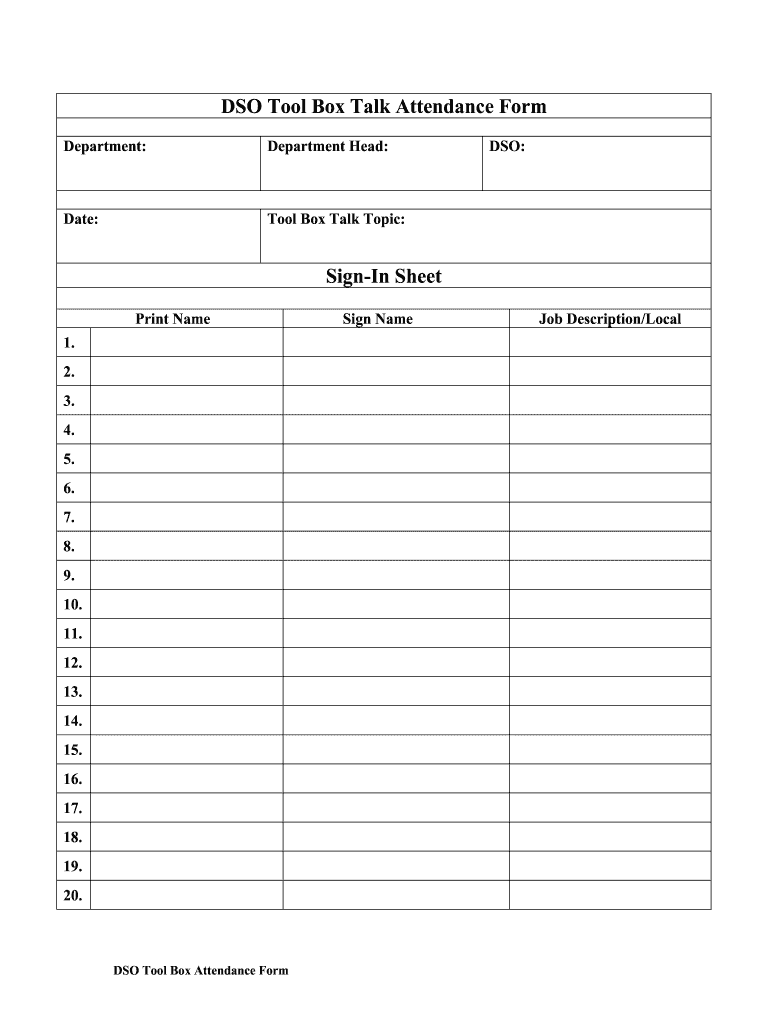

DSO Tool Box Talk Attendance Form Department Date DSO Tool Box Talk Topic Sign-In Sheet Print Name DSO Tool Box Attendance Form Sign Name Job Description/Local.

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign safety tbt format

Edit your toolbox talk template download form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your toolbox talk register excel form via URL. You can also download, print, or export forms to your preferred cloud storage service.

Editing toolbox talk format word online

To use the professional PDF editor, follow these steps below:

1

Log in to account. Start Free Trial and sign up a profile if you don't have one yet.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit tbt format word. Rearrange and rotate pages, add and edit text, and use additional tools. To save changes and return to your Dashboard, click Done. The Documents tab allows you to merge, divide, lock, or unlock files.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

Uncompromising security for your PDF editing and eSignature needs

Your private information is safe with pdfFiller. We employ end-to-end encryption, secure cloud storage, and advanced access control to protect your documents and maintain regulatory compliance.

How to fill out construction toolbox talks pdf form

How to fill out DSO Tool Box Talk Attendance Form

01

Begin with the title of the form - 'DSO Tool Box Talk Attendance Form.'

02

Fill in the date of the toolbox talk in the designated space.

03

List the names of all attendees in the appropriate section.

04

Include each attendee's job title or position next to their name.

05

Note the time the toolbox talk started and ended.

06

Provide a brief description or topic of the toolbox talk.

07

Sign the form at the bottom to certify the attendance.

Who needs DSO Tool Box Talk Attendance Form?

01

All employees participating in safety talks.

02

Supervisors and safety officers responsible for conducting the talks.

03

Management for tracking attendance and compliance.

Fill

tools box meeting form

: Try Risk Free

Our user reviews speak for themselves

Read more or give pdfFiller a try to experience the benefits for yourself

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

Where do I find tbt format pdf?

It's simple using pdfFiller, an online document management tool. Use our huge online form collection (over 25M fillable forms) to quickly discover the tbt format. Open it immediately and start altering it with sophisticated capabilities.

How can I edit toolbox talk template word on a smartphone?

You can easily do so with pdfFiller's apps for iOS and Android devices, which can be found at the Apple Store and the Google Play Store, respectively. You can use them to fill out PDFs. We have a website where you can get the app, but you can also get it there. When you install the app, log in, and start editing toolbox talk format excel, you can start right away.

Can I edit toolbox talk template on an iOS device?

Use the pdfFiller app for iOS to make, edit, and share toolbox meeting template from your phone. Apple's store will have it up and running in no time. It's possible to get a free trial and choose a subscription plan that fits your needs.

What is DSO Tool Box Talk Attendance Form?

The DSO Tool Box Talk Attendance Form is a document used to record attendance and participation in safety meetings or toolbox talks conducted by a designated safety officer (DSO) within an organization.

Who is required to file DSO Tool Box Talk Attendance Form?

Typically, the safety officer, team leaders, or supervisors who conduct toolbox talks are required to file the DSO Tool Box Talk Attendance Form.

How to fill out DSO Tool Box Talk Attendance Form?

To fill out the DSO Tool Box Talk Attendance Form, enter the date of the talk, names of attendees, signature of the safety officer, and any topics covered during the session.

What is the purpose of DSO Tool Box Talk Attendance Form?

The purpose of the DSO Tool Box Talk Attendance Form is to document participation in safety discussions, ensure compliance with safety training requirements, and track the effectiveness of safety communication.

What information must be reported on DSO Tool Box Talk Attendance Form?

The information that must be reported includes the date of the talk, names and signatures of attendees, topics discussed, and the name of the facilitator or safety officer conducting the talk.

Fill out your DSO Tool Box Talk Attendance Form online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Tool Box Talk Format is not the form you're looking for?Search for another form here.

Keywords relevant to toolbox talk attendance sheet

Related to toolbox talk form

If you believe that this page should be taken down, please follow our DMCA take down process

here

.

This form may include fields for payment information. Data entered in these fields is not covered by PCI DSS compliance.